Editor’s Note: As of 2024 there are two changes to this article:

1. Inorganic materials are sent to a separate container for incineration (not recycling).

2. The anaerobic digestion method (with beneficial use of digestate/biosolids) is now equally preferred to composting, according to the United States Environmental Protection Agency’s Wasted Food Scale.

Compostable materials collected on Harvard’s campus are used to produce energy.

By Amy Li, College ’20

Ever wonder where those banana peels end up? Well, they’ve just gotten a new home.

Composting is the new recycling. There are startups who’ll do it for you, cities who are embracing it, and multi-million dollar companies who are investing in multi-million dollar composting infrastructure projects. At Harvard, the dining halls’ dish return does it, freshman dorms have it, and the City of Cambridge has started collecting it.

Composting on Harvard’s campus is a mammoth but crucial task as the University seeks to reduce its waste footprint. Beginning in 1997, compost collected on Harvard’s campus was transported to smaller farms where it decomposed in windrows for just under a year before becoming nutrient-rich soil amendments. However, as composting efforts expanded, the amount of organic refuse collected increased. Small farms became overwhelmed with organic waste, often reaching or exceeding capacity. Compost would need to be hauled to farms as far as Maine some days or could be turned away if the farm had reached capacity. Additionally, the growth in compostable service ware like cups, forks, and plates proved challenging, as they don’t break down quickly enough in traditional compost windows.

Beginning in January 2018, the compostable materials collected in Harvard’s offices, dorms, and cafés are now used to produce renewable energy rather than soil.

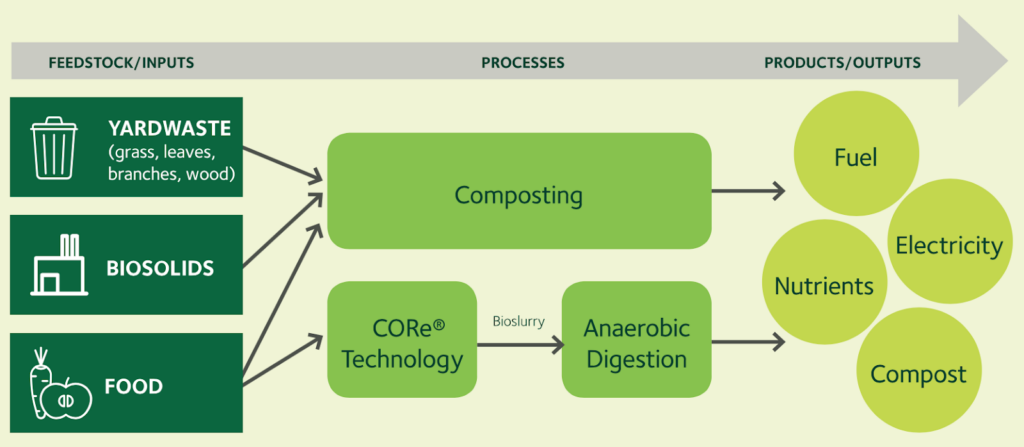

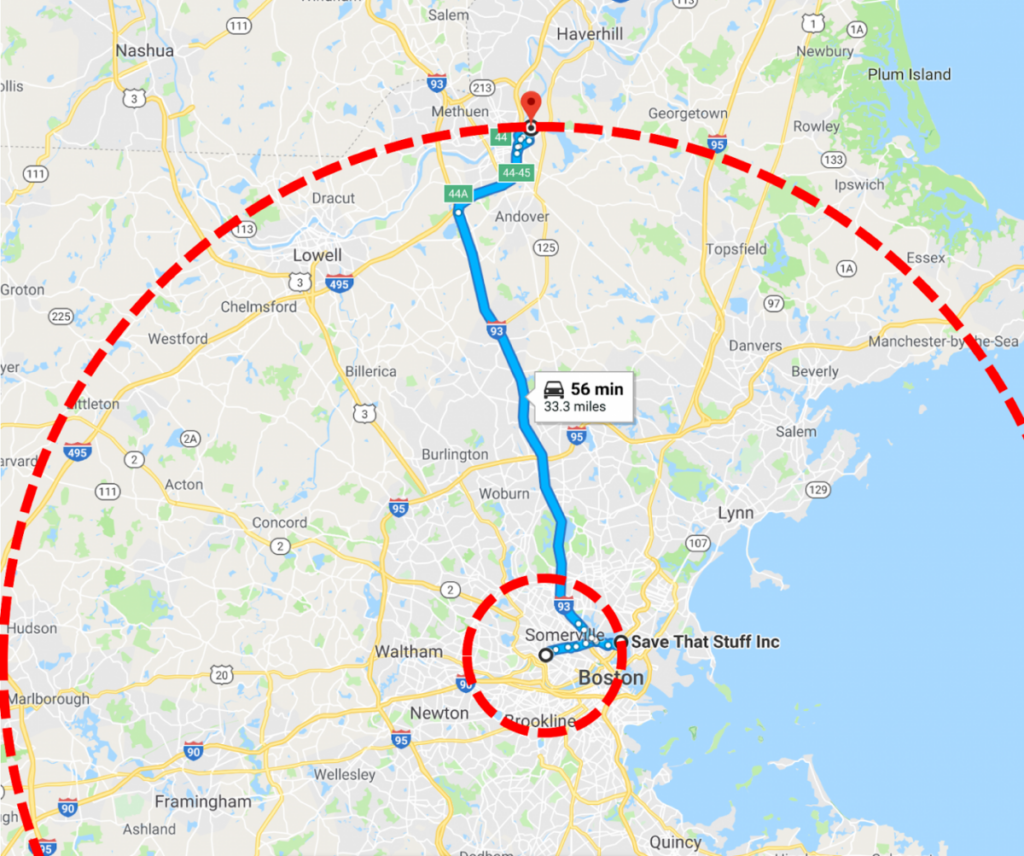

Harvard’s compost vendor Save That Stuff is partnering with waste management giant Waste Management, Inc. (WM) to send compostable materials less than five miles away to a new facility in Charlestown, Massachusetts. There, up to 500 tons of food waste a day can be processed—though it currently operates at 20 to 30 percent capacity. Collected compost is processed with a WM-patented CORe® system to produce a unique Engineered Bioslurry (EBS®), a high-energy product that is sent to a local wastewater treatment plant in Lawrence, MA to create energy in the form of methane gas.

Graphic courtesy of Waste Management ®

So how exactly does this new process work? Imagine an undergraduate House’s dining hall on a Wednesday night. For those uninitiated to the Clean Plate Club (tsk tsk), you likely have a little bit of Catch of the Day or Red Spice Chicken remaining on your plate at the end of a meal. From your dinner plate, those leftovers are taken from the ever-mysterious dish return, scraped into compost bins, and put out to be collected by Save That Stuff trucks, deep green with bright yellow logos emblazoned on the sides.

A short 20-minute drive later, the garbage trucks arrive at Save That Stuff’s sprawling Charlestown recycling and composting facility. The trucks enter the cavernous processing warehouse, tipping out that half-eaten salted caramel cake, and other organic waste on the soccer field-sized concrete floor. Walking towards the towering piles of cabbage, cilantro, and cardboard boxes, a noticeable earthy smell of produce takes over your senses, not entirely unpleasant. The wet organic material is first inspected for quality, with the facility’s employees looking for any items that might not be organic waste.

On the day I visited, tomatoes, expired loaves of bread, and several pallets of caramel sauce were loaded into a receiving hopper to be shredded in preparation for two bioseparators.

The first bioseparator spins out the organic and inorganic materials, reducing the size of organic content. Inorganic materials, like plastic wrapping and utensils or wax-covered materials, are sent to a separate container for recycling or waste. For now, plant-based plastics are also screened out as part of this process. These screened items are macerated into dime-sized flecks which are spit out into a dumpster-like receptacle to be incinerated for energy recovery. The second bioseparator further reduces the particle size of the slurry, which is sent to holding tanks that continually mix the thick liquid mixture.

Together, the bioseparators are a series of pipes and tanks, chugging away to pare down plastic-covered lettuce and biobags of food scraps into a green-brown protein-shake-resembling mix. The final product is the Engineered Bioslurry EBS®, which is optimized for strength and tested for consistency before being shipped to wastewater treatment plant Greater Lawrence Sanitary District (GLSD).

Around 10,000 gallons of EBS® is pumped daily into cylindrical trucks to be brought to the Greater Lawrence Sanitary District from the Charlestown facility where it undergoes anaerobic digestion, a process through which microorganisms “digest” organic materials anaerobically, or without oxygen. Anaerobic digesters then produce renewable energy, in the form of biogas, which powers the facilities of GLSD. At capacity, the CORe® system and GLSD partnership can convert over 100,000 tons of organic waste into this new energy source each year. This would leave GLSD with a surplus of energy while also mitigating over 347,000 gallons of fossil fuel consumption a year.

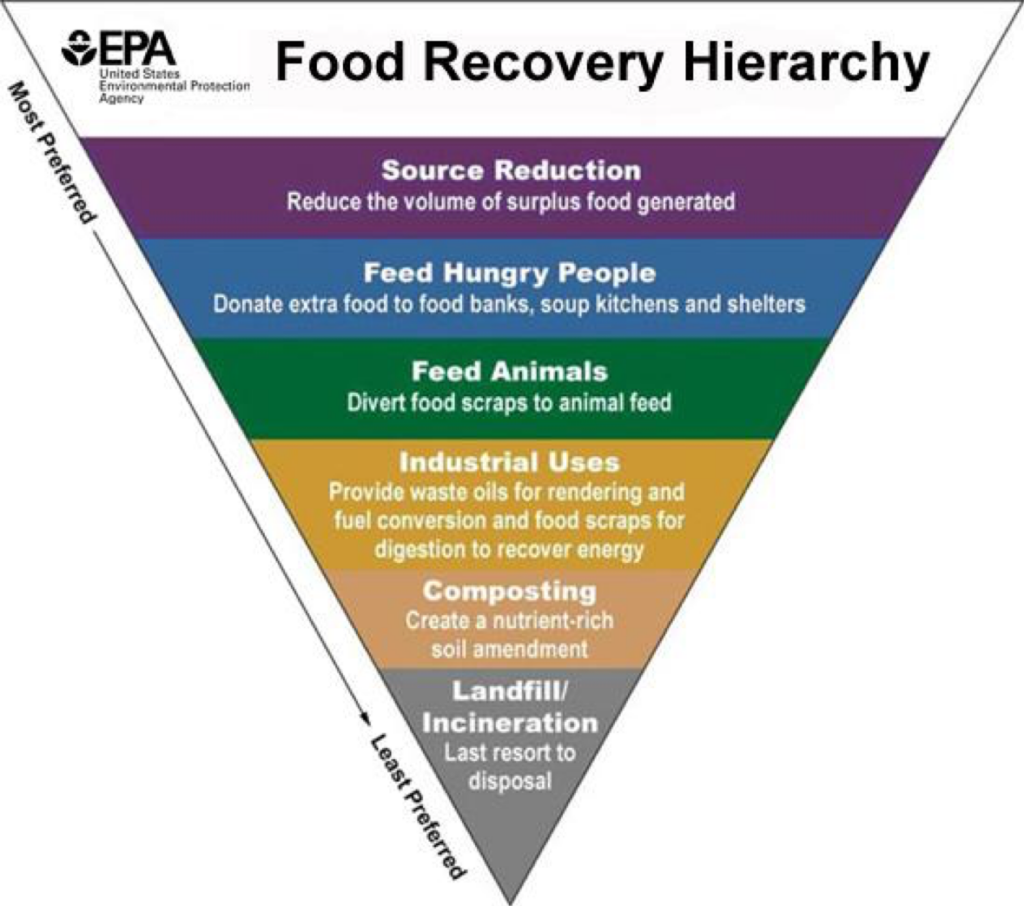

Besides the reduction in fossil fuel usage, diverting the University’s compost to an anaerobic digester has a spate of other benefits. While “composting” is considered the fifth and least best option for diverting food waste, according to the United States Environmental Protection Agency’s Food Recovery Hierarchy, putting it to “industrial uses” like anaerobic digestion is one tier above, or fourth best. Increased energy production and shorter transport times are two major advantages of this conversion method. According to WM, a 7% increase in additional organic material in the form of EBS® can increase the energy output of wastewater treatment plants’ anaerobic digesters by over 70%. This will help reduce GLSD’s reliance on fossil fuels. The CORe® system also allows for an increased quantity of organic waste to be collected and processed locally, which is crucial since one of the major limiting factors for composting in urban areas is lack of space for processing it.

While ‘composting’ is considered the fifth and least best option for diverting food waste, according to the United States Environmental Protection Agency’s Food Recovery Hierarchy, putting it to ‘industrial uses’ like anaerobic digestion is one tier above, or fourth best.

Graphic courtesy of the U.S. EPA

In 2017 alone, Harvard University produced 11,868 tons of discardable materials, including recyclables, compostables, and trash. Around 51% of the collected materials were recycled and composted, an impressive rate compared to the national rate of around one third. The average per capita trash production of 38,640 FTE (full time equivalent) students and staff at Harvard was 302 pounds, while recycling and composting combined was 312 pounds per person.

Where possible, Harvard is also prioritizing reduction of food waste as a first step. Harvard University Dining Services uses software that tracks student traffic in the dining hall and consumption of dishes in order to carefully plan for and prepare dishes with as little waste or leftovers as possible. The University is also donating excess food from the twelve undergraduate Houses and Annenberg Hall in bulk or in individually packaged meals to Food for Free, a local Cambridge nonprofit, which redistributes them to food insecure communities around the greater Boston area. Since the beginning of Harvard’s partnership with Food for Free in 2014, it has progressively decreased annual food donations through careful management of resources at the outset, shifting from about 50,000 pounds of food in the first year to the most recent tally of 27,000 pounds in 2017, translating to approximately one pound per meal. The EPA’s Food Recovery Hierarchy lists diverting excess food to “feed hungry people” as the second best option, behind “source reduction.”

The University is also donating excess food from the twelve undergraduate Houses and Annenberg Hall in bulk or in individually packaged meals to Food for Free, a local Cambridge nonprofit, which redistributes them to food insecure communities around the greater Boston area.

As Harvard has increased capacity to accept organic waste, students and members of the campus community now have more reasons to compost their food waste. When you place something in that compost bin not only are you diverting waste from landfills, but you are also helping push composting technologies forward, allowing greater volumes of organic materials to be recovered, and helping ensure that those food scraps on your plate don’t go to waste but instead are transformed into a valuable energy source.

When you place something in that compost bin not only are you diverting waste from landfills, but you are also helping push composting technologies forward, allowing greater volumes of organic materials to be recovered, and helping ensure that those food scraps on your plate don’t go to waste but instead are transformed into a valuable energy source.